Successful Factory Audit and Inspection by Dominican Clients

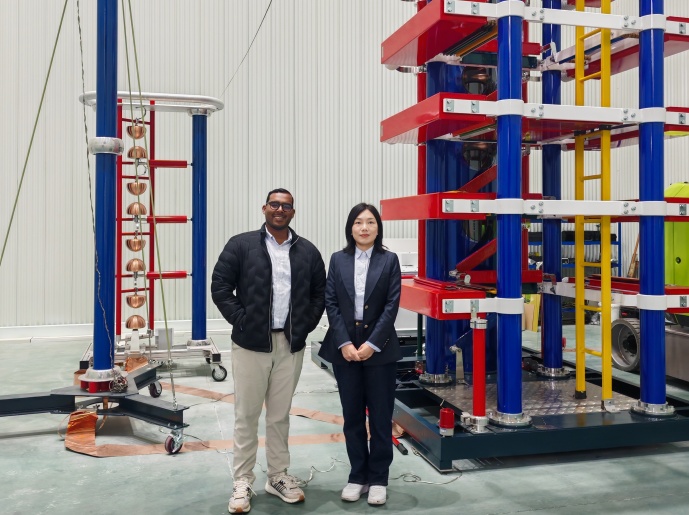

On November 13, 2025, Tengyi Electric, a premier global manufacturer of power transmission and distribution equipment, was honored to welcome a distinguished technical delegation from Dominica. The primary objective of this high-level visit was to conduct a rigorous Factory Acceptance Test (FAT) and site inspection for a bespoke order of Three-Phase ANSI/IEEE Standard Pad-Mounted Transformers.

As a manufacturer dedicated to engineering excellence, this visit underscores Tengyi Electric’s growing footprint in the Caribbean energy market and our capability to meet the stringent technical requirements of island grid systems.

Meeting ANSI Standards: A Focus on Technical Precision

The Dominican client requires robust infrastructure capable of withstanding tropical maritime environments. Consequently, the transformers manufactured by Tengyi for this project were engineered strictly in accordance with ANSI/IEEE C57.12.00 and C57.12.34 standards.

Upon arrival, the delegation was accompanied by Tengyi’s Chief Engineer and the International Project Management team. The inspection focused on the customized “American-style” box-type transformers (Pad-mounted), specifically designed with a dead-front configuration to ensure maximum safety for operators and the public.

The Factory Acceptance Test (FAT) Process

The core of the visit was the comprehensive FAT carried out in our High-Voltage Testing Laboratory. Under the observation of the Dominican engineers, Tengyi technicians performed a series of critical tests to verify performance parameters and reliability:

- Visual and Dimensional Inspection: Verification of the tank construction, corrosion-resistant powder coating (essential for salt-spray resistance), and the layout of the High Voltage (HV) and Low Voltage (LV) compartments, including Bay-O-Net fusing and load break switches.

- Ratio and Polarity Tests: Confirming the precise voltage transformation ratios across all tap changer positions.

- Winding Resistance Measurement: Ensuring the integrity of the copper/aluminum windings and internal connections.

- Insulation Resistance & Dielectric Tests:

- Applied Voltage Test: Verifying insulation strength to ground.

- Induced Voltage Test: Testing inter-turn and inter-disc insulation integrity.

- Loss Measurement: Precise calculation of No-Load Losses (Iron loss) and Load Losses (Copper loss) to ensure the units meet the high-efficiency requirements stipulated in the contract.

- Oil Quality Analysis: Verification of the mineral oil dielectric breakdown voltage to ensure optimal insulation and cooling properties.

The data collected during these tests demonstrated that all units performed well within the specified tolerances, exhibiting low noise levels and superior thermal management capabilities.

Witnessing Advanced Manufacturing Capabilities

Beyond the testing hall, the client toured Tengyi’s production workshops. They observed our automated silicon steel slitting lines, dust-free coil winding rooms, and our advanced vacuum drying and oil-filling processes.

The Dominican delegation expressed particular appreciation for our Quality Control (QC) protocols, noting the traceability of raw materials and the precision of our core stacking technology, which significantly reduces magnetic flux leakage and improves overall energy efficiency.

A Partnership for Resilient Power

“The technical expertise demonstrated by Tengyi Electric today gives us full confidence in the reliability of these transformers for our grid expansion,” remarked the Dominican client.

We are committed to providing high-quality substations, switchgear, and transformers that power communities worldwide. We look forward to the safe shipment and installation of these units in Dominica, contributing to a more stable and efficient electrical network.

We offer the best solutions for your actual requirements.

Talk to our experts to get your tailor-made solutions.