Substation

Offer custom-designed products with varying voltage levels to meet the requirements of different national power grids and provide OEM services.

Compact Substation

Compact substations are prefabricated, space-saving power distribution units integrating switchgear and transformers.

Advantages:

- Space Saving: The compact design makes them ideal for urban environments and areas with limited space.

- Reduced Installation Time: Factory assembly and pre-testing minimize on-site installation time and associated costs.

- Improved Safety: The enclosed design reduces the risk of electrical accidents and equipment damage.

Most Ideal For:

- Renewable Energy Projects: Integrating with renewable energy sources like solar farms or wind turbines, providing a point of connection to the distribution grid.

- Transportation Systems: Powering railway stations, light rail systems, or electric vehicle charging stations.

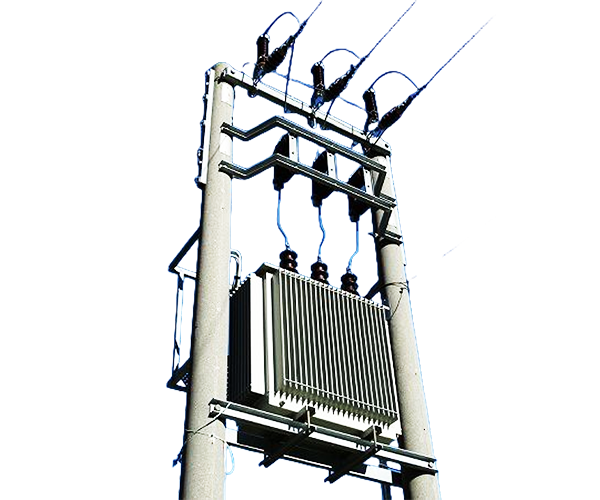

Pole Mounted Substation

Pole-mounted substations offer a straightforward and economical approach to power distribution, particularly in low-density areas or applications with limited space requirements.

Advantages:

- Compact Design: Their compact design makes them ideal for extending power lines into rural or sparsely populated regions, offering a quick and efficient solution for distributing electricity.

- Ease of Installation: Quick and easy to install, minimizing disruption and labor costs, particularly in areas already equipped with utility poles.

Most Ideal For:

- Rural Electrification: Extending power lines into sparsely populated areas.

- Low-Density Residential Areas: Providing power to individual homes or small clusters of houses.

- Temporary Power Solutions: Providing temporary power during construction or events.

- Street Lighting: Supporting street lighting systems in low-density areas.

American Style Substation

American-style substations are characterized by their robust construction and flexible design, adaptable to a wide range of power distribution needs.

Advantages:

- High Capacity: Designed to handle substantial power demands, making them suitable for large-scale projects.

- Flexibility: Modular design allows for easy expansion and upgrades as power needs change.

Most Ideal For:

- Large Industrial Facilities: Providing high-capacity power to factories and manufacturing plants.

- Utility Grid Connections: Serving as key connection points within large-scale electrical grids.

- Commercial Developments: Supplying power to large commercial complexes or shopping centers.

- Enclosure material: 201 stainless steel / aluminum zinc clad plate

European Style Substation

European designs often favor a more compact footprint, incorporating gas-insulated switchgear (GIS) to minimize the overall size and maximize efficiency.

Advantages:

- Environmental Considerations: Compact design minimizes environmental impact and blends better into urban landscapes.

- High Reliability: The use of GIS technology contributes to higher reliability and reduced maintenance needs.

Most Ideal For:

- Renovation Projects: Replacing older, larger substations in urban settings to reduce footprint and improve aesthetics.

- Public Transportation Systems: Supporting power requirements for transit systems in cities.

Mobile Substation

Mobile truck-mounted substations are housed within trailers or trucks, allowing for easy transportation and quick installation at various locations.

Advantages:

- Rapid Deployment: Quick setup and commissioning, ideal for emergency situations or temporary power needs.

- High Mobility: Easy transportation to various locations, eliminating the need for permanent infrastructure.

Most Ideal For:

- Emergency Power Restoration: Providing temporary power during outages or natural disasters.

- Special Events: Providing power for temporary events such as concerts or festivals.

- Remote Area Power: Providing power to remote locations lacking existing infrastructure.

We Focus on High Quality Substations

Our commitment to high-quality substations extends across every stage of the process, from initial design and engineering to manufacturing, testing, and ongoing support.

Superior Materials and Components: We utilize only the highest-quality materials and components sourced from reputable suppliers, ensuring durability, reliability, and longevity. This commitment to quality minimizes the risk of failures and reduces the need for costly repairs or replacements.

Rigorous Quality Control: Our manufacturing process incorporates rigorous quality control measures at every step, ensuring that each substation meets or exceeds stringent industry standards. This includes comprehensive testing and inspections to identify and rectify any potential defects before the substation is shipped.

Comprehensive Testing and Commissioning: Before delivery, each substation undergoes comprehensive testing and commissioning to verify that it performs to specifications and meets all relevant safety standards. This rigorous process ensures optimal performance and reliability upon installation.

Experienced Engineering and Design: Our team of experienced engineers utilizes cutting-edge design techniques and software to optimize performance, safety, and efficiency. This ensures that our substations are not only robust and reliable but also tailored to meet the specific needs of each customer.

900+

Total projects

80+

Marketing areas

Substation Production Details

Substation Shipment

Quote Tengyi Substation

We offer custom-designed products with varying voltage levels to meet the requirements of different national power grids and provide OEM services.

Your main circuit diagram or electrical schematic

Model, specification and quantity of your main components?

Inlet and outlet wiring method and cable specifications, etc.

Shell material and appearance: composite board, steel plate, stainless steel plate, cement board, etc.?