Power Transformer

Offer custom-designed products with varying voltage levels to meet the requirements of different national power grids and provide OEM services.

Power Transformer For Sale

Tengyi power transformer is reliable, efficient, and designed for optimal performance. Ideal for power plants, substations, large factories, and petrochemical enterprises. Ensures reliable performance for industrial and grid applications.

Main Parameters

Power rating: 6.3-240MVA

Primary voltage: 66kV; 110kV; 220kV; Customize

Secondary voltage: 6.3kV-69kV; Customize

Working Conditions

Altitude should not exceed 1000 meters.

Operating environment temperature should be between -25℃ and +40℃.

The relative humidity should not exceed 90%(+25℃).

The vertical inclination does not exceed 5°.

The outdoor wind speed does not exceed 35m/s.

Tengyi Power Transformer Advantages

Tengyi main power transformer provides efficient voltage transformation, ensuring reliable power distribution across various applications. Its robust design enhances durability and minimizes maintenance needs. Additionally, the transformer is engineered for high performance, safety, and energy efficiency, making it suitable for both urban and industrial settings.

Low Noise Levels

Minimizes environmental noise pollution, ensuring quieter operation in urban and residential areas. This feature enhances community acceptance and reduces noise-related disturbances.

Low Temperature Rise

Offers strong overload capacity, maintaining efficient operation even under high demand. This feature helps in preventing overheating and extending the transformer’s service life.

Low Energy Loss

Optimizes energy structure by reducing power loss, leading to improved efficiency and cost savings. This contributes to a more sustainable and economical power distribution system.

Minimal Partial Discharge

Ensures stable and reliable operation by reducing electrical stress, which prolongs transformer lifespan and enhances performance under various load conditions.

No Leakage Design

Tengyi power transformer provides high sealing performance, preventing oil or coolant leaks. This ensures environmental safety and reduces the risk of contamination, maintaining operational integrity.

Maintenance-Free Operation

Reduces customer maintenance costs by eliminating the need for frequent servicing. This advantage ensures consistent performance and reliability with minimal intervention.

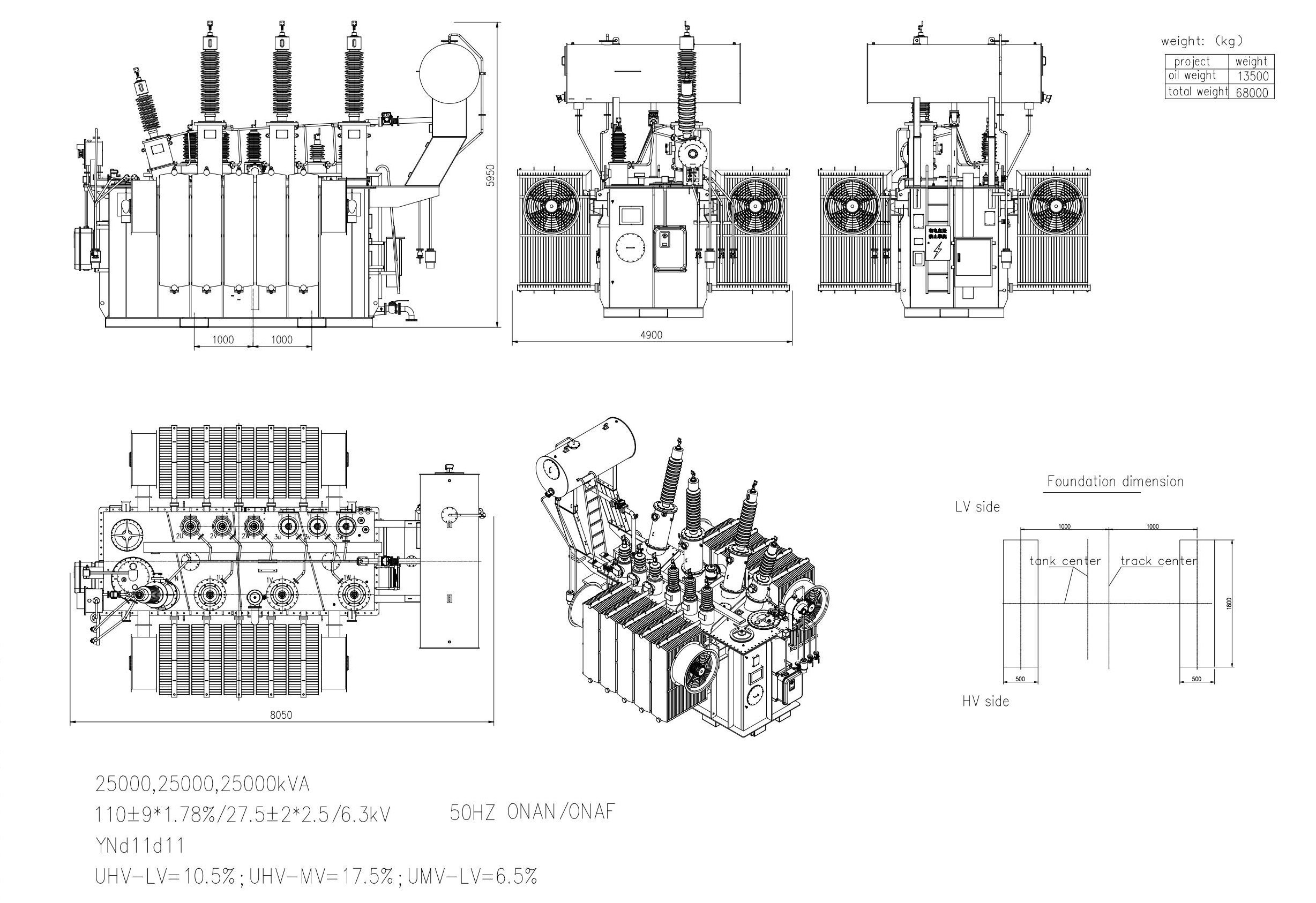

110kV, 25000kVA Power Transformer Design

Three Phase Duplex Winding Power Transformer On-Load Changer Specification

| Rated Capacity(kVA) | Voltage Combined | Vector Group | No-Load Loss(kw) | 75℃ Load Loss(kw1) | No Load Current(%) | Short-Circuit Impendance(%) | |

| HV(kV) | LV(kV) | ||||||

| 6300 | 110±8*1.25% | 6.3 6.6 10.5 11 | YNd11 | 10 | 36 | 0.8 | 10.5 |

| 8000 | 12 | 45 | 0.8 | ||||

| 10000 | 14.2 | 53 | 0.74 | ||||

| 12500 | 16.8 | 63 | 0.74 | ||||

| 16000 | 20.2 | 77 | 0.69 | ||||

| 20000 | 24 | 93 | 0.69 | ||||

| 25000 | 28.4 | 110 | 0.64 | ||||

| 31500 | 33.8 | 133 | 0.64 | ||||

| 40000 | 40.4 | 156 | 0.58 | ||||

| 50000 | 47.8 | 194 | 0.58 | ||||

| 63000 | 56.8 | 234 | 0.52 | ||||

Three Phase Three Winding Power Transformer On-Load Changer Specification

| Rated Capacity(kVA) | Voltage Combined | Vector Group | No-Load Loss(kw) | 75℃ Load Loss(kw1) | No Load Current(%) | Short-Circuit Impendance(%) | ||

| HV(kV) | MV(kV) | LV(kV) | ||||||

| 6300 | 110±8*1.25% | 35 37 38.5 | 6.3 6.6 10.5 11 | YNyn0d11 | 12 | 47 | 0.95 | 10.5 17.5-18.5 6.5 |

| 8000 | 14.4 | 56 | 0.95 | |||||

| 10000 | 17.1 | 66 | 0.89 | |||||

| 12500 | 20.2 | 78 | 0.89 | |||||

| 16000 | 24.2 | 95 | 0.84 | |||||

| 20000 | 28.6 | 112 | 0.84 | |||||

| 25000 | 33.8 | 133 | 0.78 | |||||

| 31500 | 40.2 | 157 | 0.78 | |||||

| 40000 | 48.2 | 189 | 0.73 | |||||

| 50000 | 56.9 | 225 | 0.73 | |||||

| 63000 | 67.7 | 270 | 0.67 | |||||

Three Phase Three Winding Non-Field Excitation Changer Self Coupling Power Transformer Specification

| Rated Capacity(kVA) | Voltage Combined | Vector Group | Step up Combination | Step down Combination | Short-Circuit Impendance(%) | |||||||

| HV(kV) | MV(kV) | LV(kV) | No Load Loss(kw) | Load Loss(kw) | No Load Current(%) | No Load Loss(kw) | Load Loss(kw) | No Load Current(%) | Step-up | Step-down | ||

| 31500 | 220±2*2.5% 242±2*2.5% | 115 121 | 6.6 10.5 11 35 37 38.5 | YNa0d11 | 25 | 117 | 0.57 | 22 | 99 | 0.5 | 12-14 8-12 14-18 | 8-10 28-34 18-24 |

| 40000 | 29 | 144 | 0.57 | 26 | 121 | 0.5 | ||||||

| 50000 | 34 | 170 | 0.5 | 30 | 144 | 0.43 | ||||||

| 63000 | 40 | 201 | 0.5 | 36 | 171 | 0.43 | ||||||

| 90000 | 50 | 276 | 0.43 | 46 | 234 | 0.36 | ||||||

| 120000 | 10.5 11 13.8 15.75 18 35 37 38.5 | 62 | 340 | 0.43 | 56 | 288 | 0.6 | |||||

| 150000 | 73 | 405 | 0.36 | 66 | 342 | 0.33 | ||||||

| 180000 | 84 | 463 | 0.36 | 76 | 387 | 0.33 | ||||||

| 240000 | 99 | 595 | 0.33 | 89 | 504 | 0.25 | ||||||

Three Phase Duplex Winding Power Transformer On-Load Changer Specification

| Rated Capacity(kVA) | Voltage Combined | Vector Group | No-Load Loss(kw) | 75℃ Load Loss(kw1) | No Load Current(%) | Short-Circuit Impendance(%) | |

| HV(kV) | LV(kV) | ||||||

| 31500 | 220±8*1.25% | 6.3 6.6 10.5 11 35 37 38.5 | YNa0d11 | 38 | 135 | 0.7 | 12-14 |

| 40000 | 45 | 157 | 0.63 | ||||

| 50000 | 54 | 189 | 0.56 | ||||

| 63000 | 63 | 220 | 0.56 | ||||

| 90000 | 80 | 288 | 0.49 | ||||

| 120000 | 10.5 11 35 37 38.5 | 99 | 346 | 0.49 | |||

| 150000 | 116 | 405 | 0.42 | ||||

| 180000 | 135 | 468 | 0.42 | ||||

| 120000 | 66 69 | 102 | 355 | 0.49 | |||

| 150000 | 120 | 415 | 0.42 | ||||

| 180000 | 140 | 475 | 0.42 | ||||

Three Phase Three Winding Power Transformer Specification

| Three Phase Three Winding Power Transformer On-Load Changer | |||||||||

| Rated Capacity(kVA) | Voltage Combined | Vector Group | No-Load Loss(kw) | 75℃ Load Loss(kw1) | No Load Current(%) | Capacity Assignment(%) | Short-Circuit Impendance(%) | ||

| HV(kV) | MV(kV) | LV(kV) | |||||||

| 31500 | 220±8*1.25% | 69 115 121 | 6.3 6.6 10.5 11 35 37 38.5 | YNyn0d11 | 44 | 162 | 0.77 | 100/100/100 100/50/100 100/100/50 | 12-14 22-24 7-9 |

| 40000 | 52 | 189 | 0.7 | ||||||

| 50000 | 60 | 225 | 0.63 | ||||||

| 63000 | 70 | 261 | 0.63 | ||||||

| 90000 | 92 | 351 | 0.56 | ||||||

| 120000 | 10.5 11 35 37 38.5 | 115 | 432 | 0.56 | |||||

| 150000 | 135 | 513 | 0.49 | ||||||

| 180000 | 156 | 630 | 0.49 | ||||||

| 240000 | 193 | 780 | 0.45 | ||||||

| Three Phase Three Winding On-Load Changer Word Coupling Power Transformer | |||||||||

| 31500 | 220±8*1.25% | 115 121 | 6.3 6.6 10.5 11 35 37 38.5 | YNa0d11 | 25 | 108 | 0.56 | 100/100/50 | 8-10 28-34 18-24 |

| 40000 | 30 | 132 | 0.56 | ||||||

| 50000 | 36 | 157 | 0.49 | ||||||

| 63000 | 42 | 189 | 0.49 | ||||||

| 90000 | 51 | 247 | 0.42 | ||||||

| 120000 | 10.5 11 35 37 38.5 | 64 | 307 | 0.42 | |||||

| 150000 | 76 | 365 | 0.35 | ||||||

| 180000 | 85 | 419 | 0.35 | ||||||

| 240000 | 104 | 540 | 0.3 | ||||||

About Tengyi

We are a premier enterprise specialising in designing, manufacturing, and testing a wide array of transformers.

Our advanced production facility covers over 11,000 square meters and features a maximum lifting capacity of 240 tons, allowing us to achieve an impressive annual production capacity of 12,000 MVA.

We provide transformers suitable for voltage ranges from 52 to 800 kV, with power ratings from 20 to 600 MVA, and our auto-transformers can reach capacities of up to 1,000 MVA.

Global Cases

Power Transformer Operation in Armenia

Power Transformer On-Site Test in El Salvador

Power Transformer Operation in Senegal

Power Transformer Installation in Singapore

Customer Feedback

ATAROUWAIZOUNDINE

– from Togo

Tengyi’s transformers have greatly reduced our energy losses. The low temperature rise and robust design ensure reliability, even during peak loads. We’re very satisfied with their quality and efficiency.

★★★★★

OLABODE TOSIN

– from Nigeria

The high voltage transformers we buy from Tengyi have proven to be incredibly durable. Even in harsh conditions, they maintain performance and show no signs of wear, which is crucial for our operations.

★★★★★

Power Transformer Workshop

Transformer Production Details

Transformer Shipment

Components

Core

Tengyi core uses high-quality, grain-oriented cold-rolled silicon steel sheets with high magnetic conductivity. Advanced automated shearing technology ensures burrs on the cut edges are less than 0.02 mm.

A unique non-overlapping yoke design is employed, with silicon steel sheets joined using a 45-degree full-slope stepped joint. After stacking, the core (three columns and two yokes) is compressed and bonded with epoxy resin, creating a rigid, flat assembly with high vertical accuracy. This improves no-load performance and reduces noise.

Support plates secure the core columns against the inner windings. The yokes are tightened with epoxy resin-impregnated fiberglass tape, and the lower yoke is firmly held against the lower oil tank section by counter-pressure bolts. The upper yoke is additionally secured to the upper oil tank section at three points, ensuring the transformer core remains stable and immovable within the tank during transportation.

Windings

Tengyi’s high-voltage windings utilize a stranded, continuous structure to optimize voltage distribution under surge conditions, resulting in a more uniform electric field. Rounded edges on support structures and spacers further enhance insulation reliability.

A winding internal design incorporates a meandering oil duct structure to ensure thorough cooling throughout the windings, minimizing temperature rise, reducing hot spots, and extending insulation life.

Separate tap windings are provided for high-voltage and medium-voltage regulation, balancing the ampere-turns in each winding. This effectively reduces axial electromagnetic forces during short circuits, improving the transformer’s ability to withstand sudden short-circuit events. The windings employ a “zero-margin” radial design. Thorough drying and precise fitting are implemented between the core and low-voltage winding, between the low-voltage, high-voltage, and tap windings, and between the support structures and surrounding components. This guarantees exceptional winding compactness and concentricity.

Oil Tank

The oil storage tank from Tengyi is constructed from a wide, single-piece steel sheet, formed into a corrugated structure. This eliminates welds, increasing mechanical strength and providing a dissipative effect that reduces noise. The secondary circuit wiring channels and control cabinet are made of stainless steel for a clean, aesthetically pleasing design.

All sealing surfaces are precisely machined and utilize high-quality sealing materials. The tank top features a double-sealed groove, with the outer seal protecting the inner seal from atmospheric elements and UV radiation, maximizing seal lifespan and reliability.

Other Components

Bushings: These are insulators that allow the high-voltage leads to pass safely through the tank wall without risking arcing or short circuits. They’re designed to withstand high voltages and provide reliable electrical insulation.

Insulation System: It prevents electrical flashovers (arcs of electricity) and short circuits between the windings and the core, or between the windings themselves. This system is comprised of multiple layers including solid insulation (e.g., paper, pressboard) and liquid insulation (e.g., transformer oil). The oil also serves to cool the transformer.

Tap Changer: This is an optional component, but a very common one in high-voltage transformers. It allows for adjustments to the output voltage to maintain a stable voltage level, even if the input voltage or load varies. It’s typically located on the secondary winding and can be adjusted while the transformer is energized (under load tap changing) or de-energized.

Cooling System: High-voltage transformers generate significant heat, so effective cooling is essential. This can involve oil circulation, air cooling, or even water cooling, depending on the size and power rating of the transformer. The cooling system is crucial for maintaining safe operating temperatures and preventing damage.

These components work together to efficiently and safely transform high-voltage electricity to the desired voltage level for distribution or use. The precise design and materials used will vary depending on the specific application and power requirements of the transformer.

Quote Tengyi Transformer

We offer custom-designed products with varying voltage levels to meet the requirements of different national power grids and provide OEM services.

Your main parameters of the transformer (voltage, capacity, loss and others)?

Your transformer operating environment (altitude, temperature, humidity, location, etc.)?

Other customized requirements (tap changer, color, oil pillow, etc.)?

Minimum order quantity: 1 unit