Successful Commissioning: Power Transformer Installation & Site Testing | Guatemala, 2025

We are thrilled to share the latest feedback from our valued customer in Guatemala. The recently delivered Tengyi Power Transformers has been successfully installed and is currently undergoing rigorous on-site commissioning and load testing.

Project Location: Guatemala

Client Industry: Steel Manufacturing / Heavy Industry

Project Scope: Replacement of Power Transformers (Phase 1 of 3)

Equipment: 7 Industrial Power Transformers

Antecedentes del proyecto

A prominent steel manufacturing facility in Guatemala initiated a critical modernization project to replace its aging power infrastructure. Steel plants require immense, stable, and reliable power supplies to operate electric arc furnaces and heavy machinery. The client sought a partner capable of delivering high-performance transformers that could withstand the rigorous demands of steel production.

Tengyi was selected as the supplier for this major overhaul, which involves a total procurement plan divided into three strategic batches. Each batch consists of 7 to 10 units, ensuring a phased and systematic upgrade of the plant’s power grid.

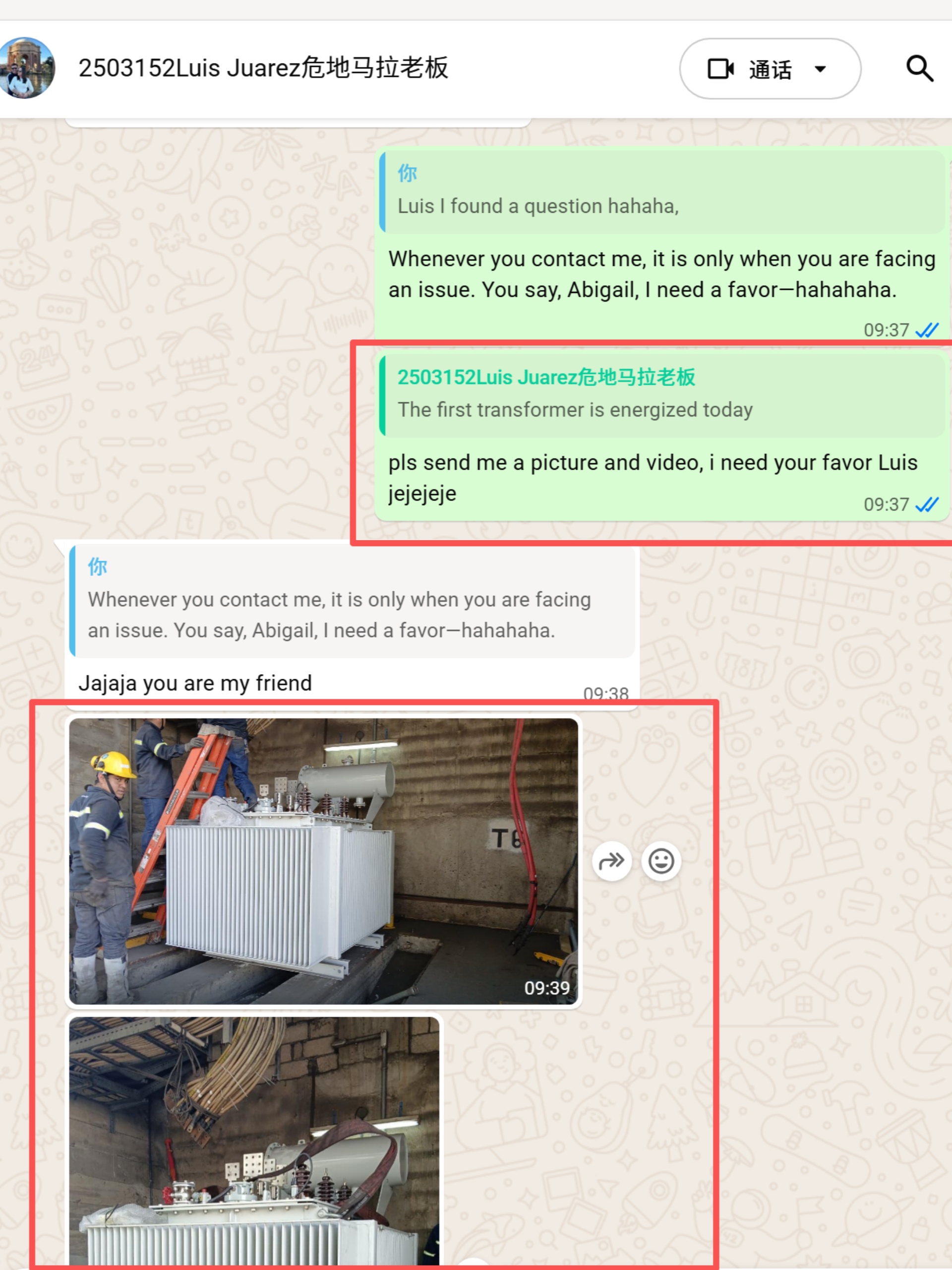

On-Site Installation

As seen in the site photos, the transformer has been securely positioned on its foundation rails. The installation process was smooth, a testament to the precise dimensional design ensuring a perfect fit with the existing facility infrastructure.

The unit features a corrugated fin tank design (as shown in the images) which provides optimal cooling efficiency while maintaining a compact footprint.

Rigorous Site Acceptance Testing

Quality does not stop at the factory gate. The most critical moment is the Site Acceptance Test (SAT). The feedback images from the Guatemalan engineering team highlight the detailed electrical testing phase.

1. Precision Monitoring

Engineers are utilizing high-precision Fluke Clamp Meters to monitor the operational current. As clearly displayed on the meter screens in the feedback photos, the transformer is operating under load with readings stabilizing around 444.0A to 445.2A.

2. Balanced Performance

The multi-cable low voltage connection (L1, L2, L3) shows excellent termination work. The consistent current readings across the phases indicate that the transformer is delivering balanced power output, perfectly aligning with the design specifications.

3. Safety First

The on-site technicians are equipped with proper PPE, including high-voltage insulating gloves (yellow), ensuring safety during the live testing of the copper busbar connections.

Client Feedback

The project manager in Guatemala expressed high satisfaction with the equipment’s build quality:

“The installation was seamless. We are currently running load tests, and the Tengyi transformer is performing exceptionally well with stable thermal and electrical parameters. The build quality of the bushings and the tank is impressive.”

Contact Our Experts Now to Get the Best Price and Most Suitable Transformer Solutions

Whether you are upgrading a steel plant or expanding a manufacturing facility, Tengyi delivers the industrial-grade reliability your operations demand. From custom transformer design to phased procurement and on-site support, we ensure your heavy machinery stays powered without interruption.